Technologies

At Amix™ Nutrition, we're driven by innovation, and our state-of-the-art manufacturing technology reflects just that. We take pride in offering a comprehensive range of sports nutrition and dietary supplements, available in various forms, including powdered blends, tablets, capsules, liquid formulations (gels), and bars.

But what sets us apart is our remarkable BAR PRODUCTION LINE with a staggering capacity of over 10,000 bars per hour. This ensures you get the highest quality bars at lightning speed.

With our primary production and warehouse facilities spanning over 22,000 square meters, we are committed to delivering excellence in every product we create. Join us in the pursuit of fitness and well-being, backed by cutting-edge technology and unwavering dedication. Choose Amix™ Nutrition for the future of your nutrition and supplement needs.

SUSTANABILITY & GREEN ENERGY

LargeLife® Limited, the owner of the AmixTM Nutrition brand, places great emphasis on sustainability. As part of our own climate strategy, the energy consumption of the entire manufacturing plant is largely covered by GREEN ELECTRICITY (Electricity generated exclusively from renewable sources).

At the beginning of 2021, a sophisticated system combining photovoltaics and large-capacity batteries (a fully automatic rooftop photovoltaic power plant) was installed. With its help, we strive to reduce the carbon footprint of the company, contribute to climate protection, and mitigate the impact of greenhouse gas emissions on the planet.

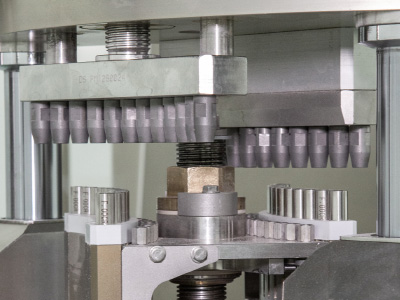

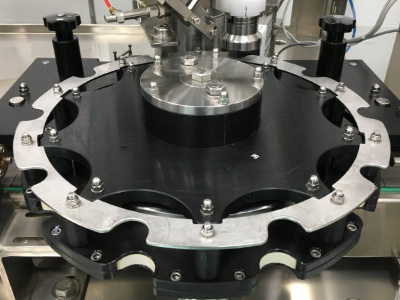

CAPSULES AND TABLETS

For the production of capsules and tablets, we use machines that adhere to the highest pharmaceutical standards.

Our capsule manufacturing equipment is fully automatic, each with a capacity of up to 100,000 capsules per hour. We use hard gelatin capsules or plant-based (vegetarian) capsules for capsule production. The filled capsules are further adjusted into blister packs or filled using an automated system into jars, boxes, and assembled into the final packaging for shipment to customers.

AMPOULES

The production of our products in ampoules takes place on a modern, fully automatic machine that assembles (decontaminates, fills, seals, and labels) the final product ready for shipment. The maximum production capacity is up to 8,000 ampoules per hour.

PROTEIN BARS

The dominant feature of one of the production facilities and the pride of the AmixTM Nutrition brand is the most modern bar production line in the Czech Republic with a capacity of over 10,000 bars per hour.

Fully automatic equipment can first process the raw dough and in the final stage wrap the bar according to preset parameters. In our portfolio you can find both classic protein bars, muesli bars and nutty bars such as Protein Nuts.

LIQUID PRODUCTION AND GELS

The manufacture of liquid forms of dietary supplements involves mixing solutions and then filling them into bottles or sachets. The pride of this division is a fully automatic production facility with a capacity of up to 580 bags per minute.

Here we also produce gels for endurance sports such as Quick Gel, Slow Gel or Nitro Gel.

POWDER PRODUCTION

We process more than 10 tons of bulk mixtures every day. The entire production process starts with a request to the automated production system, according to which the worker accurately weighs the individual raw materials.

These are further mixed and processed for subsequent use throughout homogenisation. Depending on the requirement, the resulting mixture is adjusted into doses or bags or filled into capsules and pressed into tablets.

CARBONATED DRINKS

To fill carbonated beverages into cans, Amix uses state-of-the-art technology designed for products of the highest quality. Canning is a simple and safe way to preserve the long-lasting taste, aroma and effective ingredients while protecting the contents from oxidation and sunlight.

DEVELOPMENT CENTER

The newly opened production and shipping facility also includes a modern research and development centre. Here we are continuously working on the development of new products and constantly innovating our existing portfolio.

Our team is also experienced in custom product development, taking into account the specifics of the markets for which the products are intended. For example, different taste preferences or legal import requirements.

WAREHOUSE & DISPATCH CENTRE

The newly opened production and logistics centre also includes a modern automated warehouse.

The ever-increasing demand and requirements for speed of dispatch convinced us to invest in a fully automatic Jungenheinrich shelf stacker, which processes the assigned transport and storage tasks completely independently and with maximum reliability.

Our production systems are fully automated. Due to the precise registration of stock quantities and production capacities, we are able to plan the production of the required product in the shortest possible time and dispatch it to the customer.

PATENTS

For the production of AmixTM Nutrition sports nutrition we primarily use patented raw materials that guarantee consistent quality and pharmaceutical purity. Years of work by our development department, combined with insights from the field from our ambassadors, have led to the identification of previously undiscovered synergistic effects and thus the creation of new products. We currently work with more than 40 patented raw materials from around the world. For more information about the patents, please visit the following link.

QUALITY GUARANTEE

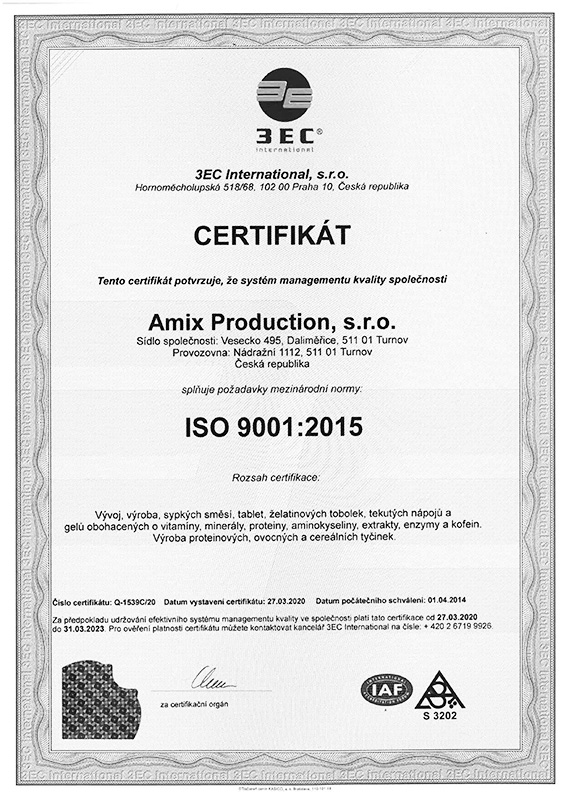

- Holder of the certification system HACCP, ISO 9001, ISO 22000 and GMP (Good Manufacturing Practice).

- Year 2018 - FOOD SAFETY CERTIFICATION FSSC 22000 (Food Safety Management System).

- Under constant supervision and regular audit of the Czech Agriculture and Food Inspection Authority

- The HACCP System that we introduced has helped us and still helps to detect and eliminate possible threats to the customer‘s health. This system allows for the control of the whole production process – from the moment that the rough products are received up to the point when the final products are completed - thus safeguarding that the customer enjoys healthy products.

- The Quality Management System based on the ISO 9001:2015 norm reflects the actual high standards of our company and ensures their constant optimisation.

- Holders of the ATUSALVD award from the Ministry of Health in Spain as the best brand of sports nutrition for its quality and innovation for 2017.

|

Certifications of the management system and food safety |

Management system and food safety |

Hazard Analysis and Critical Control Point management |

Quality management system |

.png)